How to Reduce or Increase Porosity in Ceramic Processing

Ceramic porosity is one of those topics that material science teams wrestle with week after week. Too much of it, and you start battling strength issues, moisture absorption, and frustrating rejects. Too little of it, and drying becomes risky, firing curves get tight, and you lose the breathability that certain products require.

Types of Porosity

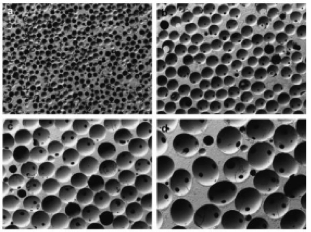

Before we get into adjustments, it helps to think about how porosity behaves inside a ceramic body. Open porosity connects to the outside surface and affects drying, permeability, coatings, and how moisture moves through the piece. Closed porosity stays trapped internally and influences density, thermal behavior, and shrinkage. When an operation sees porosity swings, the balance between open and closed pores often shifts first. Often one of the most significant challenges is control pore size needed for particular applications such as catalysts, catalyst supports, filtration, refractories, and ceramic insulators.

Factors That Reduce Porosity

After decades on production floors, we can tell you that porosity control is far from theoretical. It’s practical, hands-on ceramic processing, and it’s shaped by everything from raw materials to the operator adjusting a press or an extruder, a granulator, or kiln.

1. Higher Forming Pressure

Pressures in many ceramic plants range anywhere from 150 MPa for basic structural bodies to well over 300 MPa for denser technical parts. As pressure climbs, particles rearrange and collapse voids that would otherwise stay open. Uniform pressure across the die face matters just as much as the absolute value. Any uneven loading, worn tooling, or moisture pockets can create local zones of higher or lower porosity. When plants bump pressure by 10-20%, it’s common to see a measurable drop in open porosity and a tight bump in fired strength. Pressure, forming method, particle size, organic materials involved, and firing temperature tend to impact porosity the most.

2. Finer Particle Size Distribution

Shifting a body’s D50 down by even 5-10 microns can noticeably tighten the pore structure. Fines settle into the gaps between coarser particles, reducing voids and raising fired density. When you are working with submicron materials for mesoporosity, often raw material selection can be critical. A key metric will involve the surface area of the material often driven by the particle size. This is not always the case as some materials such as zeolite are inherently a porous structure with high surface area.

Many plants track PSD alongside moisture and forming pressure because an unexpected rise in coarse fraction often causes porosity to creep upward. The tradeoff is that finer PSD can increase plasticity or stiffen an extrusion mix, so adjustments to water or plasticizer levels may be required.

3. Longer Milling or Mixing Time

Well-dispersed slurries and powders pack closer together. Extra milling time often tightens particle groupings and brings down ceramic porosity. Forming methods from fluid bed coating to spray drying techniques can often determine the layering or packing of the coating or a coating over a substrate.

4. Higher Sintering Temperature or Longer Soak

Raising peak kiln temperature by even 25-50°C (77-122°F) can reduce total porosity by 1-3% in many alumina‑ and silica-based formulations. The reason is simple: higher temperatures promote neck growth and phase development that collapse remaining pore volume. Longer soak times achieve a similar effect, though they add to fuel cost and throughput time.

Plants usually tighten up this lever only after evaluating raw materials and forming, since firing changes tend to influence shrinkage, warpage, and dimensional stability. The time to temperature as well as firing atmosphere from oxidation to inert also play a role in porosity. It is not just peak temperature but often the soak time at a given peak temperature.

Factors That Increase Porosity

As with any ceramic body, there are times when you want a more open structure. Filtration products, lightweight bodies, ceramic proppants, catalysts, or insulation materials all benefit from higher ceramic porosity. These adjustments shift the body in that direction without overcomplicating day-to-day production.

1. Coarser Materials or Additives

A controlled addition of coarser particles increases air pathways. This technique is common in filtration ceramics and thermal insulation products where higher ceramic porosity is the goal. Often a bimodal distribution is needed to create the level of micro vs meso vs macro pores.

2. Burnout Materials

Organic pore formers such as sawdust, paper fiber, walnut shell, or engineered polymer beads or flakes such as polypropylene are widely used when a controlled, predictable increase in porosity is needed. Most additions fall between 5%-15% depending on the product. These materials typically burn out between 250-350°C (482-662°F), leaving a network of voids behind. The key is balancing pore former size with body shrinkage because too large and you risk bloating; too fine and you may not gain enough permeability. Plants also watch for black core or carbon retention when burnout ramps too slowly.

Inorganic non oxide pore formers such as silicon carbide or silicon nitride that also play a role to create specific porosity in certain technical ceramic applications such as cordierite mixtures.

3. Reduced Forming Pressure

Lower compaction produces more voids and a lighter structure. This also eases drying but can require tighter control during handling. The challenge most often is reducing the forming pressure to a point that yields the porosity needed but also does not sacrifice green and fired strength of the product.

4. Lower Firing Temperature

Underfired pieces retain more open structure. Use this carefully since mechanical strength and water absorption may be directly affected.

Operational Tips from the Plant Floor

Ceramic porosity is one of the most influential properties in any plant making tiles, refractories, technical ceramics, or structural clay products. Controlling it means balancing raw materials, forming, and firing in a way that fits your equipment and your operators’ daily reality.

- Track porosity against each stage of ceramic processing instead of only at final inspection. You’ll spot shifts long before they become rejects.

- Utilize BET surface area and mercury porosimetry to generate defined metrics of your porosity. Simpler methods such as Archimedes absorption testing are often needed on the plant floor for solutions in daily production.

- When troubleshooting porosity swings, start with forming and raw material moisture. These two variables cause more headaches than most realize.

- Firing adjustments should be the final lever you pull. Raw materials and forming usually offer easier, lower-cost corrections.

Work with the Ceramic Processing Experts at IntoCeramics

If porosity swings are eating into yield or creating inconsistent performance, the IntoCeramics manufacturing consulting team can help. With decades of hands-on ceramic processing experience behind us…we’ve seen nearly every cause of porosity drift and helped plants correct it quickly!

Our ceramics experts support plants with:

- Toll manufacturing solutions

- Research & development

- Analytical testing services

- Business development

Contact us online when you’re ready for expert ceramics manufacturing support.