Precision Milling & Grinding

With our expertise and cutting-edge equipment, IntoCeramics is your trusted partner in unlocking the full potential of your materials through precision milling solutions.

IntoCeramics Custom Milling Services

Milling is the process of reducing the size of materials to achieve desired characteristics, properties, and particle size. Whether it’s crushing large materials to smaller sizes or refining them to ultra-fine particles, milling plays a crucial role in various industries, from manufacturing to research and development.

Our milling services include:

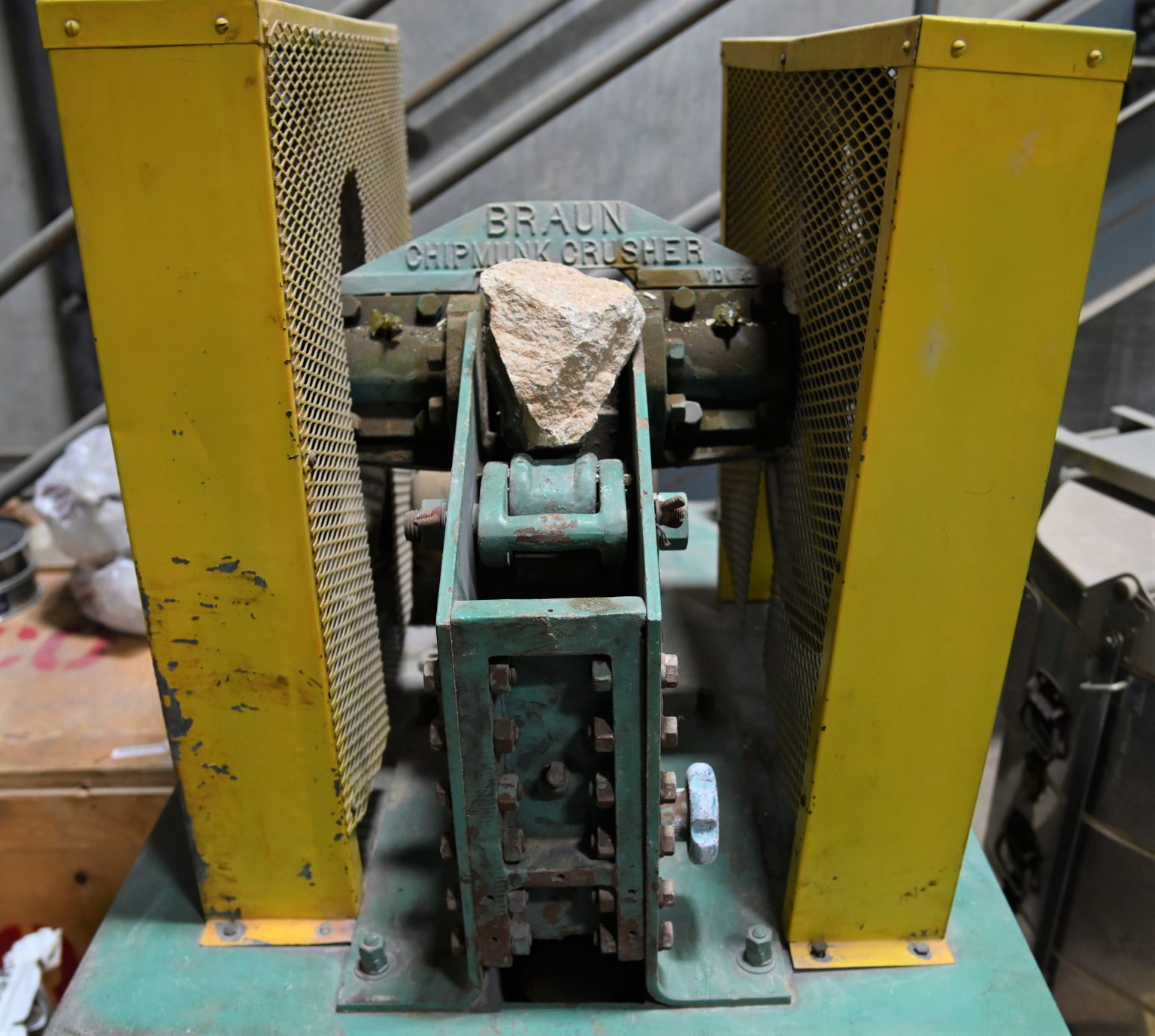

Jaw Crushing

Preparation of large-diameter materials for further size reduction, ensuring efficient processing for downstream applications.

Roll Grinding/Pulverization

Coarse grinding of dry materials to achieve desired particle size distributions, optimizing material properties for various industrial uses.

Ball Milling with Ceramic and Steel Media

From fine to ultra-fine grinding, our ball milling services excel in both dry and wet environments, delivering precise particle size control and superior product quality.

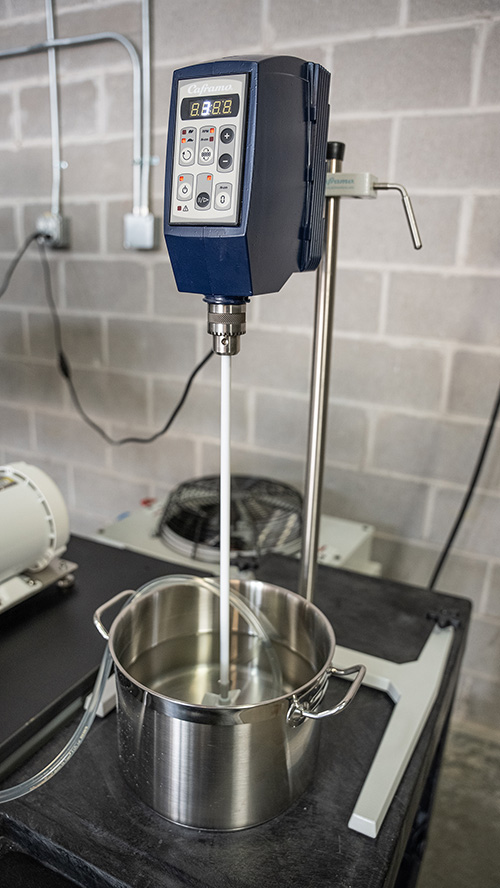

Wet Media Attrition Bead Mill

Experience fine to ultra-fine milling in wet slurry conditions, enhancing material performance and enabling innovative product development.

Quality Analysis and Sizing

Rely on our comprehensive quality analysis and sizing services to ensure the integrity and consistency of your materials, meeting API, ISO, and multiple ASTM standards. Our services include onsite laser diffraction particle size analysis with our state-of-the-art Shimadzu analyzer.

Screening

Utilizing Sweeco and Ro Tap equipment, we offer screening solutions across all sizes, from coarse to fine, ensuring uniformity and precision in your final product.

Physical Testing

Benefit from our expertise in physical testing, including API, ISO, and various ASTM procedures, guaranteeing the reliability and durability of your materials.

Helium Pycnometer

Leverage our helium pycnometer for rapid specific gravity determination, providing essential data for material characterization and optimization.

Optical Imaging

Harness the power of optical imaging technology for advanced analysis and visualization of your materials, enabling precise control and enhancement of product properties.

Get in Touch

Additional Milling Equipment

IntoCeramics offers cutting-edge milling solutions tailored to meet your unique needs. From coarse grinding to ultra-fine milling, our state-of-the-art equipment delivers exceptional results every time.

Micro-Jet Milling Machine

The microjet mill is an advanced milling solution designed for high-precision dry grinding / milling and contamination-free processing. With all ceramic material contact points, this machine is ideal for achieving ultra-fine particle sizes in a controlled environment. Material dependent but most minerals will jet mill <3um d50 particle size.

Features:

- Efficient design with reliable operation for consistent results

- All ceramic contact points to prevent contamination

- Enhanced clean air system provides clean and dry air to ensure contamination-free milling

- Capable of reducing particles to micron and submicron sizes

- Operates within a precise, adjustable range, producing finished product sizes from 3 to 45 microns

- Variable cylindrical chamber for flexible grinding and classification

Applications:

- Fine grinding of ceramic materials

- Production of micron and submicron powders

- High-precision material processing

- Research and development in material science

(click to expand)

40-Liter Planetary Mill

The 40-liter Planetary Mill is a versatile and efficient milling solution designed for smaller batch sizes and finer particle sizes. Utilizing small-sized grinding media, this machine offers precise control over the milling process, achieving particle sizes below 10um with ease.

Features:

- Capable of achieving finer particle sizes (<10um)

- Utilizes small-sized grinding media for precise control

- Media options include alumina, zirconia, and YTZ

- Higher energy input enables faster milling times

- Ideal for applications requiring quick turnaround and high throughput

Applications:

- Fine grinding of ceramic materials

- Production of ultra-fine powders

- Research and development in material science

- Preparation of samples for analysis

(click to expand)

100 Liter Ball Mill – Ceramic or Stainless Lined

The 100 Liter Ball Mill represents industrial-scale milling at its finest, offering larger volume capacity and the ability to process larger feed sizes. Equipped with larger media, it excels in coarse grinding applications, producing final particle sizes typically around 325 mesh. This equipment is a game-changer for our toll manufacturing capabilities, allowing us to process much larger volumes of material with efficiency and precision.

Features:

- Produces final particle sizes typically around 325 mesh

- Boosts toll manufacturing capabilities for large-scale production

- Suitable for rough and fine grinding or mixed materials

- Dry and wet grinding methods

Applications:

- Coarse grinding of ceramic materials

- Large-scale production of powders and granules

- Toll manufacturing for industrial applications

- Processing of bulk materials for various industries

(click to expand)

Additional Images:

(click to expand)