Understanding the IntoCeramics Stage Gate Project Methodology

The stage gate process is a technique used to guide a project from conception to completion. At IntoCeramics, we are admirers of Dr. Bob Cooper and his Stage-Gate® innovation process. With his business associate, Dr. Scott Edgett, Cooper founded Stage-Gate International. This global company helps innovators and emerging companies bring new products to market with an agile and cost-effective process.

Our training as engineers and scientists and long experience in the ceramic industry has led IntoCeramics to follow stage gate models and checklists tailored to our clients’ needs.

Using Project Stage Gates to Help Our Clients

IntoCeramics’ clients range from individuals with a bucket of sand to Fortune 50 companies — and their needs are all different.

Some clients are very clear about what they want to do. They enlist us to help their team develop markets. For example, they might ask us: “We have product X that we’d like to introduce to industry Y for use as a replacement material in process Z. Can you help us do that?”

Others are less clear, coming to us with a material and saying, “Do you think this mineral A could be used somehow, somewhere?”

Still, others simply ask, “I don’t have any idea what this stuff is — can you tell me?”

Despite their differences, they all want to reach a goal, even if they don’t know precisely what that goal should be. This is where IntoCeramics comes in, especially if the ultimate goal is unclear to both the client and us.

IntoCeramics’ Stage Gate Phased Approach

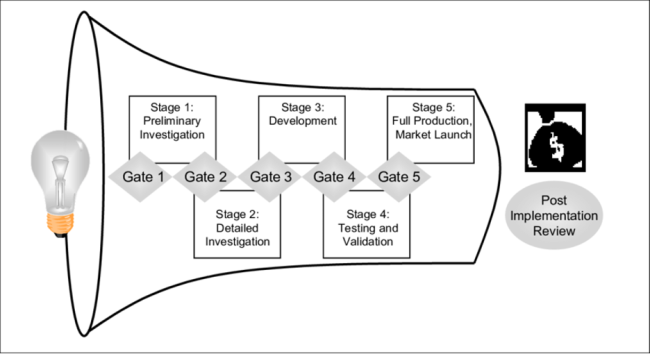

Following the Stage-Gate® methodology, IntoCeramics uses a flexible process determined by several go/no-go decisions.

Decision Zero: Is it Possible?

We would much rather give a quick “no” than a long, drawn-out “maybe.” Our experience and training have equipped us with the knowledge to sometimes reach this conclusion. We can’t turn lead into gold any more than we can turn quartz into alumina.

More often, the situation merits further investigation, and we discuss options with the client before proceeding with Phase 1: Laboratory Analysis.

Decision One: What is the Potential?

Using a laboratory scale sample, we perform a visual and physical examination of the candidate material. We carry out a suite of analytical tests, which may include X-ray diffraction for mineralogy, X-ray fluorescence to determine elemental chemistry, loss on ignition for organic content, specific gravity, bulk density, and other tests indicated by the nature of the material.

Based on this initial analysis, we form an opinion on the potential for turning the material into something useful. If the chemical and mineral composition offers little prospect of converting the material into a saleable product (or feedstock for a manufacturing process), the project can be wrapped up.

We report the results and our opinion to the client and jointly decide whether to proceed with Phase 2: Lab Scale Processing.

Decision Two: Does it Have Commercial Potential?

The next phase of the stage gate model addresses whether it makes sense to process the material and what the market potential might be for the resulting product.

This is where IntoCeramics’ research and development capabilities come to the fore. We use the source material to formulate, produce, and test different end products, blending it with other materials when needed.

We assess the product’s physical and chemical properties each time to determine their suitability for commercial applications. This can range from the customary brick, tile, and sanitary ware markets to less obvious applications such as lightweight aggregate, manufactured sand, and colored glass manufacturing.

If there appears to be a pathway to commercial development, we produce high-level capital expenditure and operating cost estimates to support a financial decision, and we assess environmental and regulatory issues.

Once again, unless the results are commercially compelling, IntoCeramics will recommend that no further investigation is warranted. However, if the results show promise, we will extend our discussions with the client to Phase 3: Upscaling and Pilot Processing.

Decision Three: Can it be Produced at Scale?

As we often say, we’re not interested in making the world’s greatest 100 grams of product. Instead, we focus on making the world’s greatest thousand, ten thousand, or hundred thousand tons of product.

Phase 3 of our stage gate methodology is where we must upscale the process developed in the laboratory to show that the products and processes can be replicated at an industrial scale. This requires great care and effort to prove that Phases 1 and 2 can be upscaled.

Using either IntoCeramics pilot-scale facilities or a third-party manufacturing partner, we produce pilot product batches ranging from hundreds to thousands of pounds, depending on testing requirements. We then submit samples to independent testing laboratories for verification.

Assuming the process upscales satisfactory, we then support our clients in designing a full-scale manufacturing facility. This involves designing the overall process flow, associated facility footprint, and capital equipment specification.

With a detailed facility design in hand, we can produce highly accurate capital expenditure and operating cost forecasts. This is the critical point at which we can direct the client team in approaching the final investment decision. If everything still looks good, we will guide the client through Phase 4: Commercial Implementation.

Decision Four: What is the Best Route to Commercial Success?

We’ve come a long way by this point. Having determined that a previously unquantified material can be turned into something of value and that the process to do so can be scaled up in a commercially viable way, it’s time to select and implement a business model.

We assist our clients in selecting the best way forward, which usually involves choosing between (a) building and commissioning their own manufacturing plant, (b) licensing the material and process to a third party, or (c) having the material processed by toll manufacturer. Finally, we reach the most fun part — implementation!

IntoCeramics has years of boots-on-the-ground facility construction, commissioning, operations, and optimization experience.

We support our clients all the way from the first “what is this stuff?” lab inquiry to operating an efficient, profitable, full-scale manufacturing plant that turns their waste material into a valuable ceramic product.

The Bottom Line

At IntoCeramics, we have the manufacturing consulting and ceramic engineering expertise to help our clients reach their goals. However, we’re not afraid to tell them when it can’t be done. We will only deliver good news when the data and testing prove that it really is good news and not just folly. We’re here to help you reach your goal, not lead you down a garden path.

Contact us today for more information about our stage gate methodology and ceramic consulting solutions!